KIESELSTEIN is a historical world leader in the field of draw-peeling (shaving) of wire, relying on its own research and development centre to further develop a unique technology to remove wire surface defects, whether steel or non-ferrous.

SEQUEM and KIESELSTEIN GmbH inform you.

KIESELSTEIN offers a complete range:

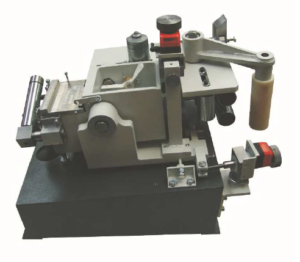

- SHAVING UNITS: all-in-one compact systems offering the complete shaving technology: calibrating and shaving dies, chip-breaker, chip disposal, cooling. This unit can be integrated into existing wire-drawing lines.

- SHAVING LINES: including all auxiliary pay-off, straightening and coiling equipment.

- SHAVING TOOLS: the shaving dies are state-of-the-art technology

KIESELSTEIN also has its own in-house shaving plant, offering the possibility to test your shaving application and provide samples for you. Should you require even more information, simply download the brochure here.

SEQUEM remains at your disposal for any inquiry. Contact our team at +33 3 28 80 55 60 or by e-mail at sequem@sequem.fr.

Nederlands

Nederlands Français

Français Deutsch

Deutsch English

English