Twee keer per jaar geeft de EBNER Group een nummer van haar nieuwsbrief HICON uit: een gelegenheid om iets meer te weten over de EBNER Group en haar drie afzonderlijke entiteiten (EBNER, GAUTSCHI en HPI) die apparatuur voor de staal-, aluminium- en koperlegeringsindustrie aanbieden.

Het laatste nummer kan worden gedownload door op de onderstaande afbeelding te klikken:

Geen tijd om alles te lezen?

We hebben een selectie van onmisbare artikelen voor u samengesteld !

Hoge kwaliteit = hoge klantentevredenheid

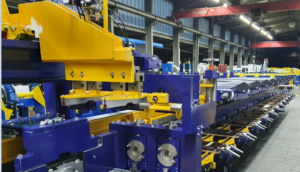

EBNER klok-gloeierij voor staaldraad

ECOBURN H2

Nieuwe EBNER brandertechnologie combineert duurzaamheid en efficiëntie

Atmosphere Perfect Wire

Nieuw toebehoor voor 20% besparing op elektriciteit en waterstof

Alle oudere edities zijn direct beschikbaar op de website van de EBNER Groep.

Wilt u snel meer informatie?

SEQUEM, uw exclusieve EBNER en GAUTSCHI-agent, geeft u graag meer informatie.

Contactez notre équipe à l’adresse sequem@sequem.fr ou au +33 3 28 80 55 60.

Nederlands

Nederlands Français

Français Deutsch

Deutsch English

English