BÜLTMANN invites you to drop by! !

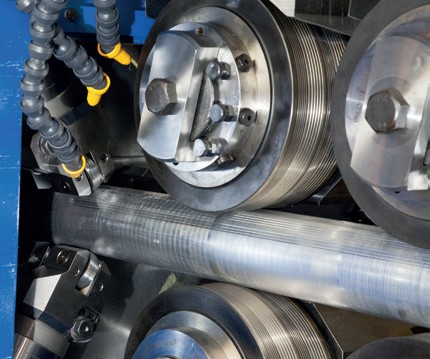

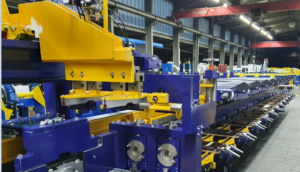

A new piece of equipment is currently on display at BÜLTMANN: the multi roll straightening machine type SRM 5/7-120s. In addition to it, the production line comprises a pre-straightener, a shot-blasting unit, facing and chamfering equipment, a testing line, a sawing unit as well as a sorting and packing system.

Interested? SEQUEM will be happy to support you in developing your project! In the meantime, please note that this new straightening machine will be exhibited at BÜLTMANN until February 21st, 2020, so don’t miss it!

To find out more about this straightening machine, please read the information below:

Technical data

- Material: pre-straightened and shot-blasted steel bars

- Bar diameter: 40 – 120 mm

- Bar length: 3.0 – 12.0 m

- Straightening accuracy: < 0,8 mm/m

- Straightening speed: 10 – 120 m/min

- Straightening force: 5 x 1200 kN / 2 x 600 kN

Special features and highlights

- Extremely robust construction of the individual components ensures a long service life

- Automatic adjustment to material-dependent parameters

- 5-roll principle for good and homogeneous straightness

- Short maintenance, change-over and tool changing times

- High flexibility for future demands

Contact

You can write us an e-mail by clicking here or call us at +33 (0)3 28 80 55 68.

SEQUEM is at your disposal for any additional information you may need.

Deutsch

Deutsch Français

Français English

English Nederlands

Nederlands

…denn das Event zieht viele Besucher an! Bei der letzten Messe vor zwei Jahren wurde eine Rekordzahl verzeichnet: noch nie hatten die Aussteller insgesamt so viele Quadratmeter gebucht! Absolut beispiellos in der Geschichte des Drahtes und Rohres.

…denn das Event zieht viele Besucher an! Bei der letzten Messe vor zwei Jahren wurde eine Rekordzahl verzeichnet: noch nie hatten die Aussteller insgesamt so viele Quadratmeter gebucht! Absolut beispiellos in der Geschichte des Drahtes und Rohres.