SEQUEM is happy to invite you to the WIRE & TUBE trade show,

the most eagerly awaited event in the wire, cable and tube industries!

Who will be exhibiting?

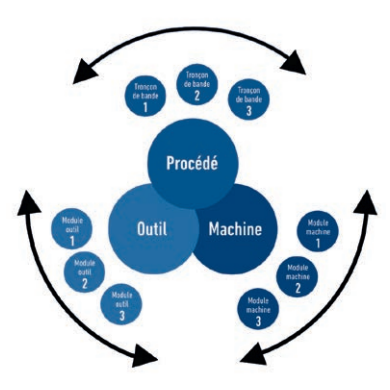

As the sole representative of several manufacturers in those industry sectors, SEQUEM will be present at the show to attend visitors with its partners, all of which are major suppliers of equipment and accessories for the production of metal wires, rods and tubes, power cables, flat metal products, punched and bent metal parts or subassemblies…

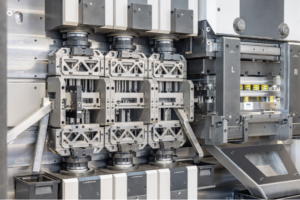

- BIHLER, Hall 10, Stand F18

- BRAUN, Hall 10, Stand D42-03

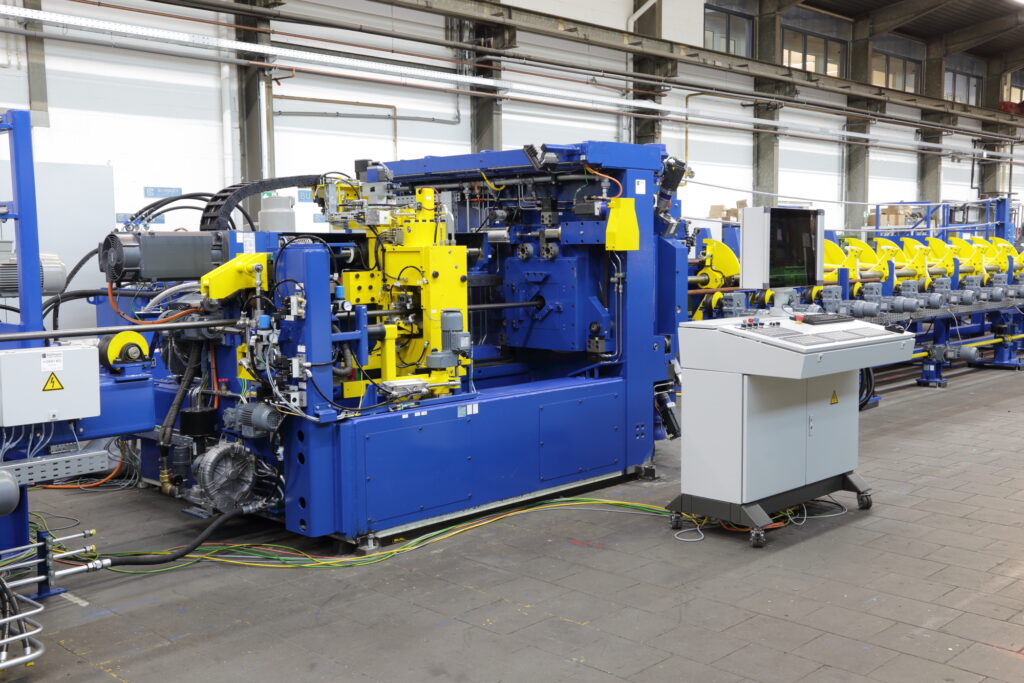

- BÜLTMANN, Hall 6, Stand C27

- EBNER, Hall 10, Stand D42-04

- EJP WIRE TECHNOLOGY, Hall 9 / Stand A12

- HÄFNER & KRULLMANN, Hall 9, Stand A25

- KIESELSTEIN, Hall 10, Stand H18

- KRENN-KAMAX, Hall 10, Stand G66

- KROLLMANN, Hall 12, Stand A39

- LEIMBACH, Hall 9, Stand B14

- M+E, Hall 10, Stand H55

- NIEHOFF, Hall 10, Stand D22

- PLASMAIT, Hall 10, Stand C42-05

- ROSENDAHL, Hall 9, Stand A60

- SIRIO WIRE, Hall 10, Stand H55

- SKET, Hall 10, Stand G18

- STRECKER, Hall 10, Stand A21

- WAFIOS Hall 10, Stand F22-40

- WITELS ALBERT Hall 9, Stand E39

- WITHÖFT, Entrée Nord, Stand EN06

- WOYWOD-PLASTICOLOR, Hall 9, Stand A42

- WTM, Hall 11, Stand D78

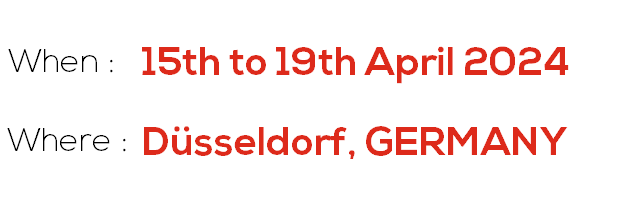

Mark your calendar

PMake sure you do not miss this must-attend event and add it to your favourite calendar app with a click!

Stay ahead!

First come, first served! Book your appointment now with François or Pierre SERVAES. They will walk you through the show and present you with the suppliers and products that can best meet your needs and business.

- Meet the major market players

- Explore the innovations in the wire, cable and tube technologies

- Discover the latest market trends and future developments

Deutsch

Deutsch Français

Français English

English Nederlands

Nederlands